The Current Method is Slow, Costly and Dirty.

Current asphalt paving machines, with their flat screeds, are only adequate when used on a flat surface. They have NO ability to incrementally adjust the amount of asphalt that is delivered across the width of the surface to be paved.

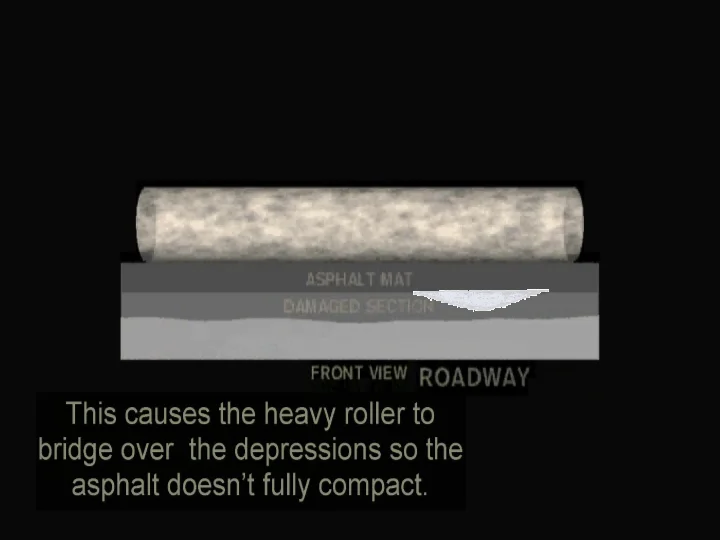

For example, if a flat layer of asphalt is laid down over an existing road surface that has typical road deformities (such as bumps, dips or ruts), they don't deliver enough material over the depressions. So when the heavy roller comes along the material around the depression compacts first, causing the roller (with its flat compacting surface) to bridge over the depression and the asphalt material doesn't fully compact. When this happens, either the material continues to compact over time and the original depression re-appears, or it starts to crack.

After cracks form, water seeps in, which further breaks down the asphalt.

And the dreaded pothole appears.

When this happens they must close down the road again to patch the pothole, which unfortunately is really only a band aid. Eventually the road gets bad enough and the entire surface must be rehabilitated.

The current method is to mill down the surface flat so current asphalt paving machines, with their flat screeds, can be effective.

The milled material is then hauled away, remixed and hauled back to repave the original surface. Unfortunately, this method re-processes 100% of the road surface to address a much smaller percentage of problem areas. Structurally, nothing is wrong with the majority of all asphalt that is reprocessed in this manner. This method is very time consuming and costly, as well as greatly contributing to the carbon output of the project. It also causes more and longer lane closures, which costs you time and money and causes even more carbon output as we idle in traffic congestion.

Every year in the U.S. alone, more than 90 Million Tons of asphalt are reprocessed in this way.

You see, they can't just mill out the damaged sections because they must provide a uniform flat surface for the flat delivery method of current asphalt paving machines to be effective. So they mill down every square inch of the road surface and reprocess it in this way. The industry touts this as a recycling effort, however it’s anything but a green process!

This inefficient process continually restarts costing us time, money and impacting the environment. All because current asphalt paving machines deliver asphalt with a single flat surface. They are a quasi 2-Dimensional tool being used to address a 3-Dimensional problem.

Up until now the technology did not exist to do it any other way. But that is all changing...

Click here to Read about Our Solution

Sign up for our News Letter to keep informed about our efforts.